What is Bubble Jet Cleaning?

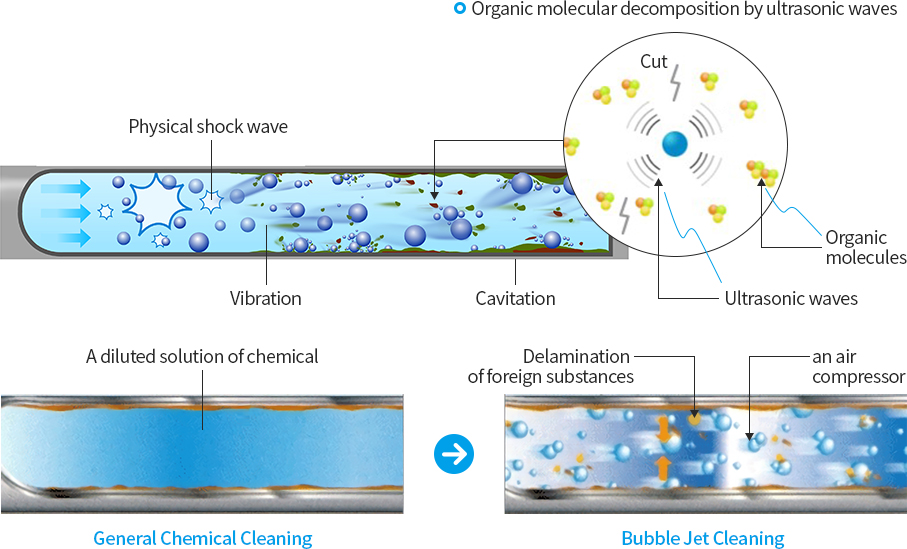

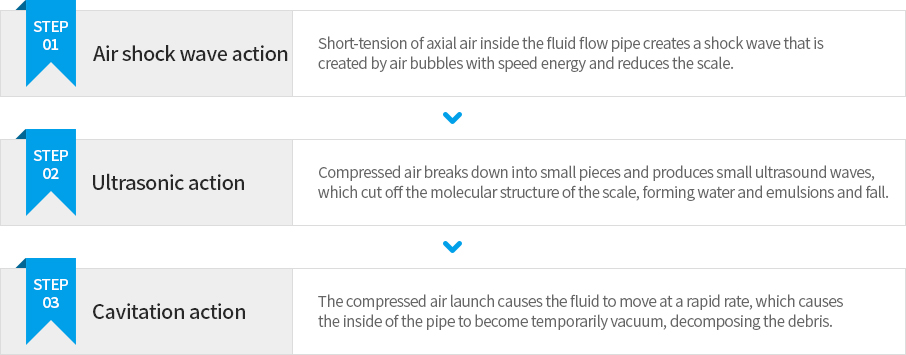

If compressed air of between 3 and 5 kg/cm is repeatedly shooting & stopping inside the pipe where the cleaning agent flows, the bubble will pop and cause physical shock, vibration, and fine ultrasound. This physical action removes the scale and increases the reaction speed of the chemical to maximize the cleansing effect, which is three to five times greater than conventional chemical cleansing. In addition, fluid flows rapidly and slowly across, with the cavitation of sound pressure forming on the surface of the pipe repeated to increase the delamination of the scale.

Bubble Jet Cleaning demo video

Principles of Bubble Jet Cleaning

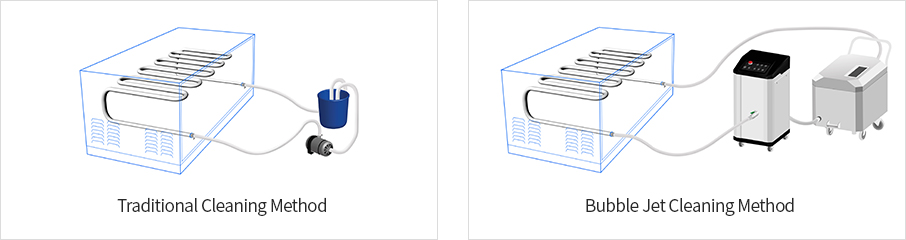

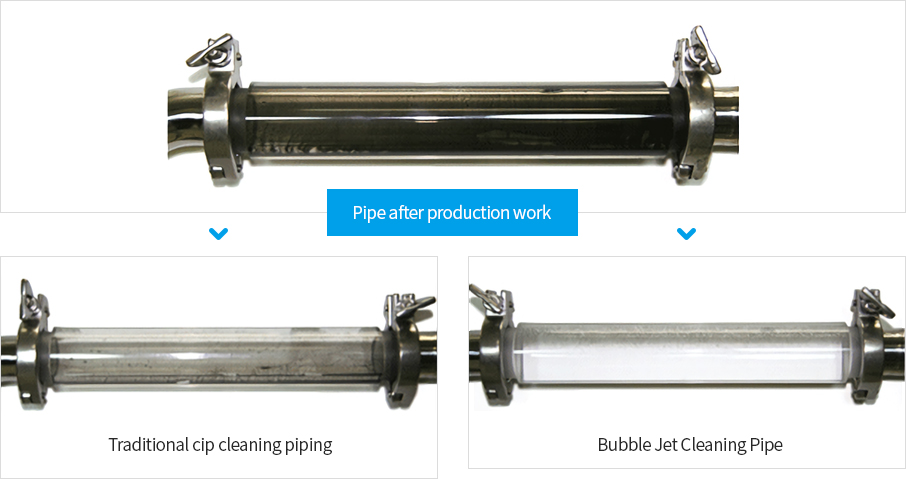

Difference between Traditional and Bubble jet Cleaning Methods

Traditional cleaning methods were cleaned by diluting the chemical with a pump and plastic container and simply circulating them.

There is a high possibility that the chemical can be poured out during the operation or that the chemical will bounce due to residual pressure during removal of the connecting hose, resulting in injury to workers or corrosion of facilities.

The Bubble Jet cleaning method has 3 to 5 times effects then the Traditional cleaning method.

There is a high possibility that the chemical can be poured out during the operation or that the chemical will bounce due to residual pressure during removal of the connecting hose, resulting in injury to workers or corrosion of facilities.

The Bubble Jet cleaning method has 3 to 5 times effects then the Traditional cleaning method.

Applied to Bubble Jet Cleaning Method

- Applied to : Industrial piping, heat exchanger, condenser, chiller, oil cooler, special piping, etc.

- Scope of application : Applicable to piping of all materials

- Pipe Diameter : 10~200mm / Cleaning length of piping is over 1000m.

Effect of Bubble Jet Cleaning Method

Bubble Jet Cleaning Equipment : Circular

Bubble Jet Cleaning Method Features

- 3 to 5 times greater cleaning power than in previous years

- 30 % to 50 % less cleaning agents, 1/2 less cleaning time, and lower costs

- Reduced reject rate of production products, reduced energy through scale removal