What is Passivation?

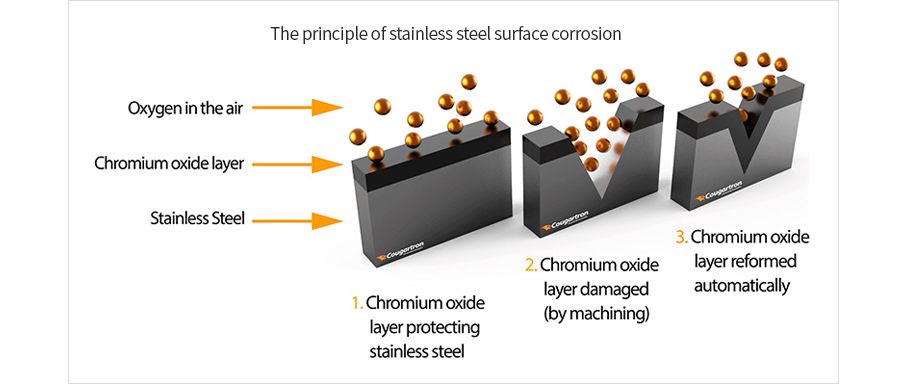

The phenomenon in which corrosion products in metals suppress the surface by covering the surface is called corrosion control. Stainless pipes are basically coated with thin oxide film for rust protection when produced at the factory. The reason why stainless pipes does not get rusty is due to the nature of the material, but the aid of oxide coating is also great. However, due to the high temperature of welding, the ingredients of the material changes and the coating is peeled off and cause rust. Passivation is the formation of an anti-corrosion oxide coating using acids.

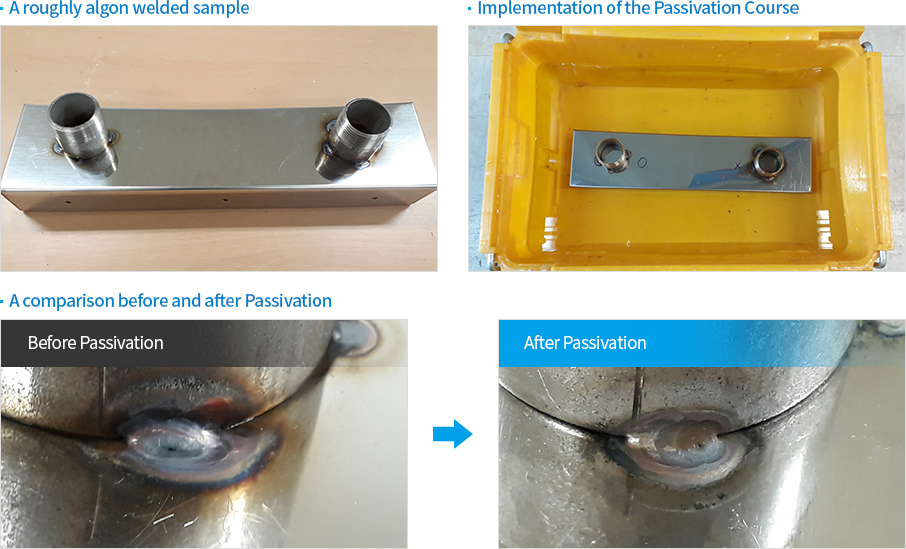

Passivation test for Stainless pipe weld site

This experiment performed an alkaline cleaning and acid passivation test on the test bed after the pipe was welded roughly to the stainless plate.

- Result : After passivation working, the weld debris, hydrocarbons has been removed.

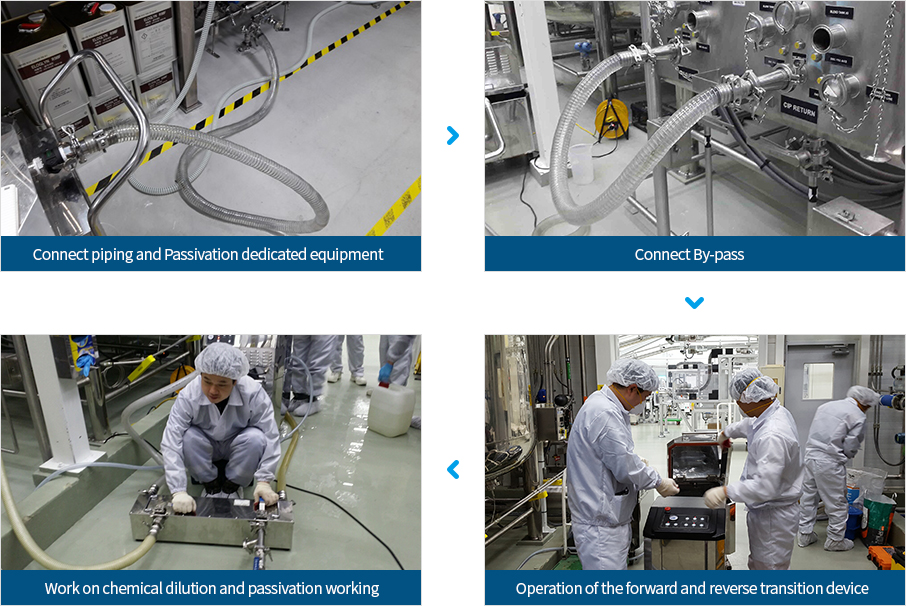

Passivation Work Methods

The Passivation process requires the removal of any oil stains on the surface of the stainless piping using alkaline cleaning agents and contact of acid to form the oxide film.

Semiconductor, Bio Pipe Parts Passivation case

We provide passivation services with the Passivation Work Manual presented by NASA. Please understand that we are unable to disclose the specific working manual and chemical on our website.