What is the Wire brushing technique?

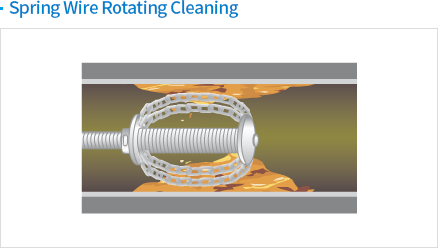

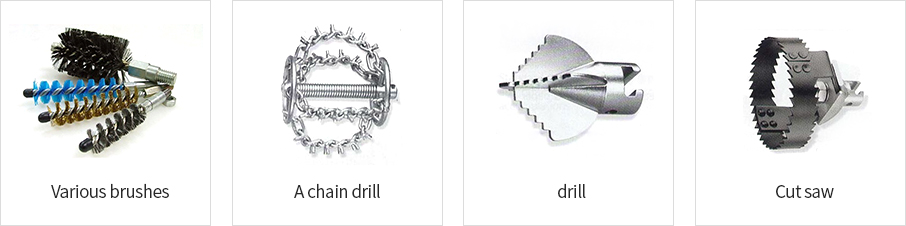

A technique for mounting brushes or drills on the end of a spring wire and inserting them into a pipe to remove the scale as the wires rotate.

It works well because the scale is removed by the physical friction of the brush.

If the scale is very hard, which is not removed by brushing, it can also be crushed with a drill tip.

It works well because the scale is removed by the physical friction of the brush.

If the scale is very hard, which is not removed by brushing, it can also be crushed with a drill tip.

Principles of Wire Brushing Method

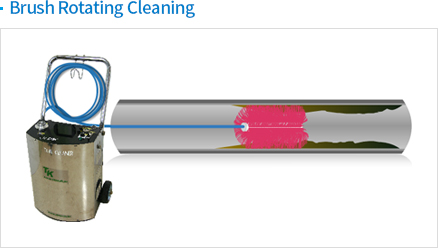

Apply wire brushing technique to

- Applied to : Industry heat exchanger, piping, raw material piping, wastewater piping, special piping, etc..

- Scope of application : Shell & Tube Type Heat Exchanger, Industrial Pipe

- Pipe Diameter : 15~300mm / Cleaning length of piping is less than 50m.

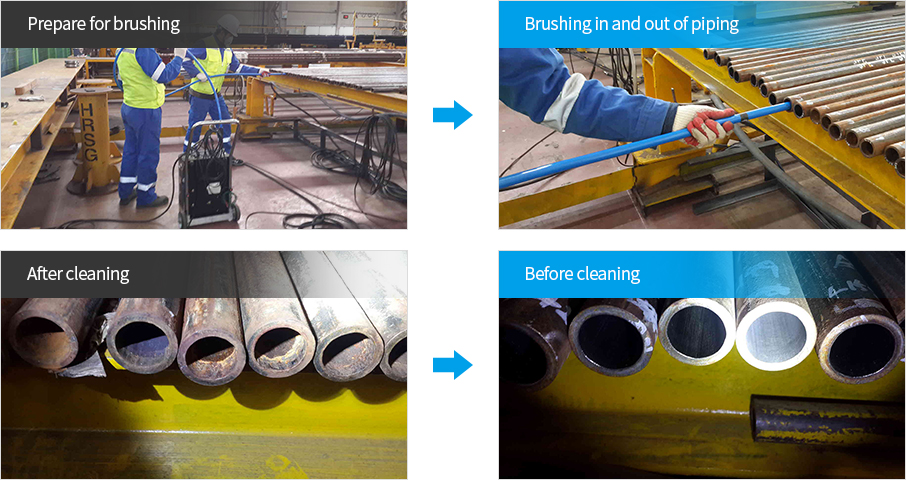

Wire brushing cleaning example

Advantages and disadvantages of wire brushing

- Advantage :

- Fully scale out with the power of a brush or drill

- Weakness :

- The length of the spring wire can not be extended indefinitely, so the length of the pipe can be cleaned is limited to a maximum of 5m or less.

In addition, for curved or branching pipes such as elbows and T, one point can be goes in, but more than two points can not be goes in.